Testing

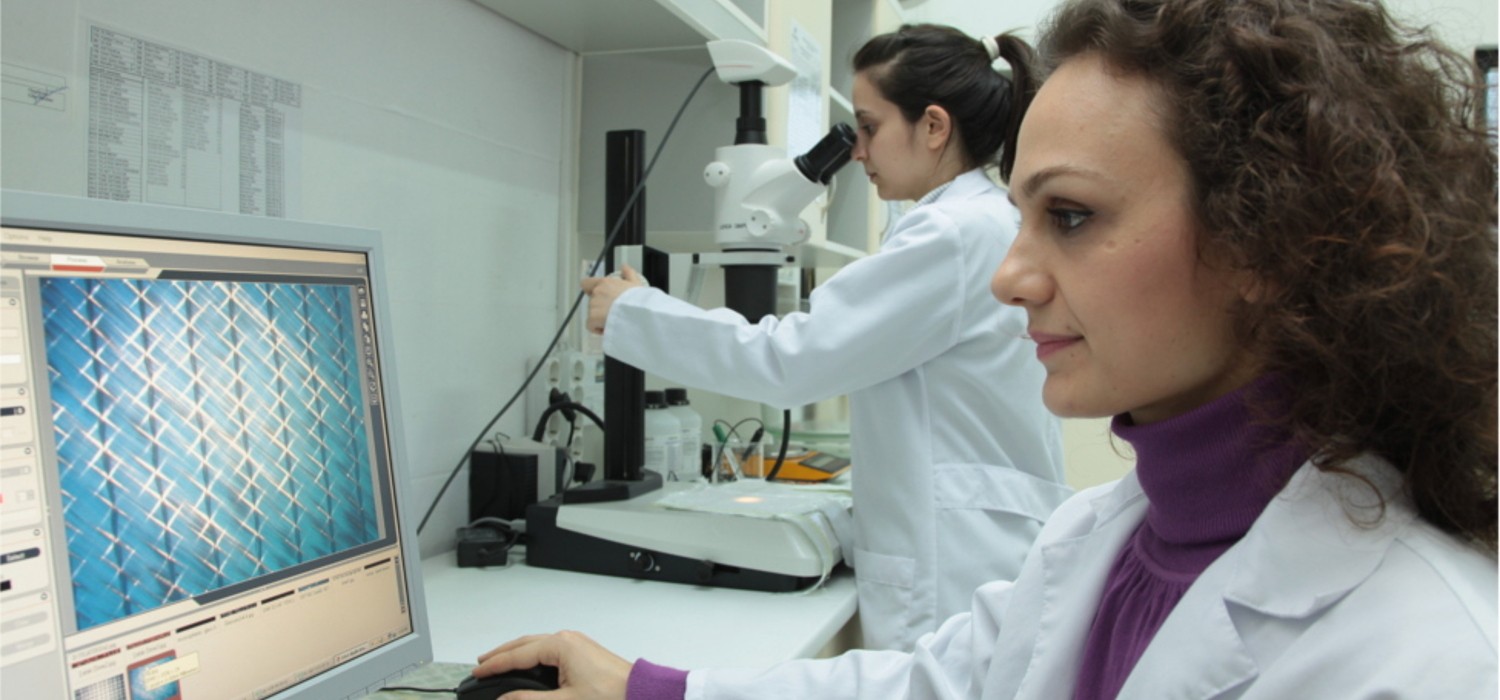

METYX Composites offers extensive laboratory and testing services for the domestic and international composites community.

Our highly skilled and trained staff produces laminates with any resin (polyester, vinylester, and epoxy) by several production processes, including hand layup, infusion, RTM, and hot press.

Laminates with a thickness range of 2 to 30 mm can be produced in an RTM test mold. Infusion laminates can be produced up to 4 mt in length, and thick monolithic sections can easily be achieved. The METYX Composites Test Lab includes an 80 ton lab scale hot press with a plate size of 500 mm x 500 mm. Temperatures as high as 350 degrees Celsius can be reached to produce not only thermoset laminates but thermoplastic laminates as well.

Finished laminates are cut with precision via CNC, and the specimens are tabbed in the most reliable way.

Our universal testing machine with a capacity of 100 kN ensures accurate testing within ASTM and ISO related standards.

- Tensile strength and modulu

- Flexural strength and modulus

- ILSS and in-plane shear tests with modulus

- Compression tests with end or shear loading

- Poisson’s ratio

Other physical, optical, and analytical tests can also be run in our labs.

- Density

- Barcol hardness

- Void content

- Detailed analysis of fibers and textiles

- Micro scale analysis by stereo microscope with bright and dark field lamination

- Fiber and filler content by burn out or acid digestion

- Moisture content