Tooling Centre

METYX Composites Tooling Center

METYX Composites has invested in a dedicated Tooling Business Unit, located in the 23,000 sq. m ‘state-of-the-art’ production facility at Manisa, Turkey, where glass multiaxial reinforcements and custom kits are also manufactured.

The METYX Composites Tooling Centre was set up in response to identified customer and market needs. It aims to offer design engineering and manufacturing support to customers looking for affordable, high quality tooling solutions.

The METYX Composites tooling team has particular expertise in large scale tooling projects for:

- Wind blade mould components

- Hull and deck plugs and moulds for boatbuilding

- Complex design tooling for automotive & transportation

- Multiple component architectural projects

- Direct negative mould for limited volume parts

Tooling Engineering Services & Support

METYX Composites offers engineering support, using state-of-the-art design and production software, to customers in all industrial market sectors.

- Engineering support

- Reverse engineering

- Rapid prototyping

- Tooling consultancy

Master Plug (Pattern) Production

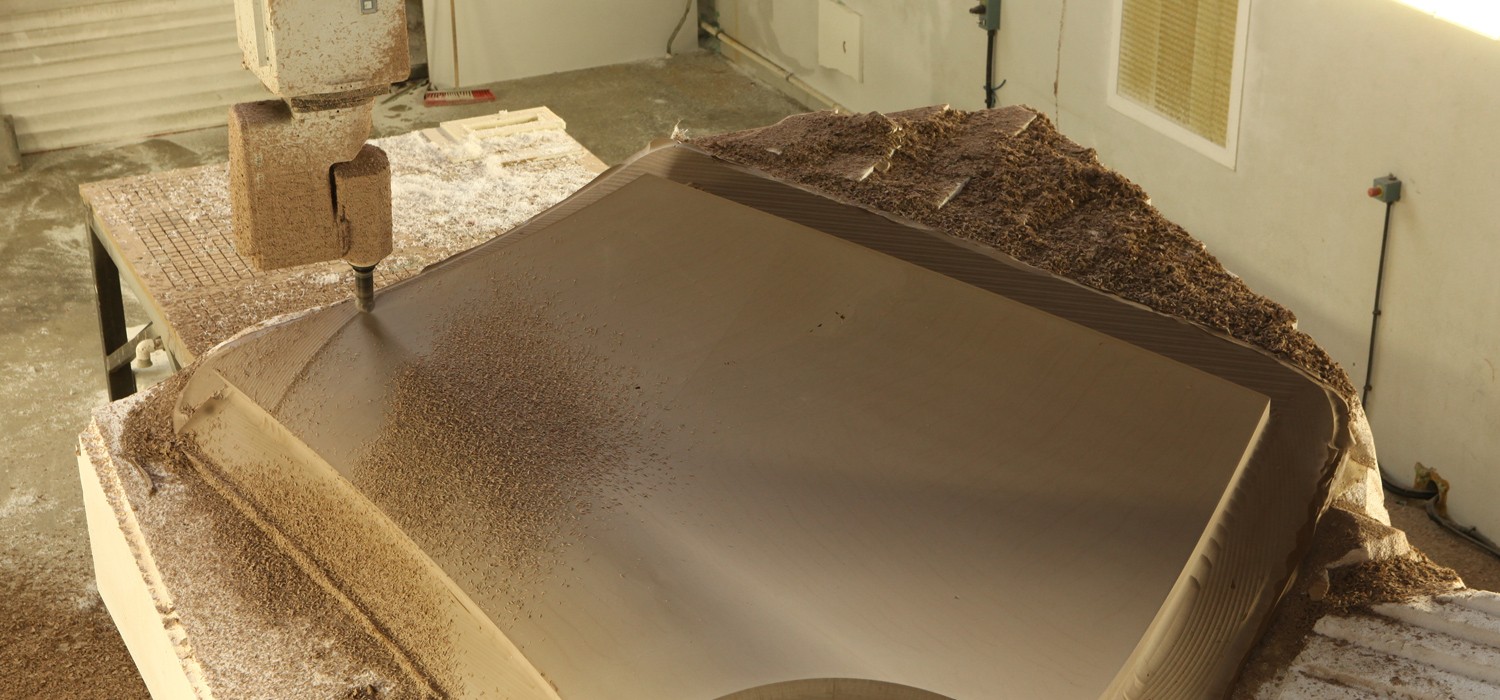

Standard master plugs are typically manufactured using a tooling board or foam-based glass reinforced laminate base, onto which and epoxy or polyester paste is applied. Once set, the paste is then precision

CNC milled to create the final surface before finishing. The last step is the application of a primer and top coat, which is finely sanded and polished to a high gloss surface finish.

Master Plug Making Materials:

- Tooling board

- PU and Epoxy foam

- Polyester and Epoxy paste

- Primer and Top coat

Master Plug Features:

- Shape stability, with 5-axis CNC milled accuracy and finish

- Large plug production capabilities – up to 10m x 6m x 4,5 m

- High gloss polished surface finish

- Modular production of single or multi sectioned plugs

- Double gel coating and post curing to order

FRP Mould Tool Production

FRP moulds with the required mechanical properties needed for moulding finished composite components are produced from the high quality, surface defect free master plugs. Large scale single and multi-split FRP moulds are produced for: hand lay, spray up, RTM, and infusion processes.

Direct Negative Moulds

Tooling Centre also produces large-scale moulds using a direct moulding technique, which is a very cost effective solution for producing prototypes and for one off or limited run components, especially for projects with a limited budget or tight timescale needed a fast tooling solution.

FRP Mould Tool Making Materials:

- Polyester rapid tooling resins

- Epoxy tooling resins

- Vinyl ester and epoxy tooling gelcoats

- Custom reinforcement solutions manufactured by METYX Composites

FRP Mould Tool Features:

- Only quality tooling materials used for high durability

- Mould shell supports as needed for tool life.

- Excellent part production repeatability

- Water based heating system options

- Laser scanning

- QC documentation

- Mould commissioning

The METYX Composites Tooling Centre cost effectively provides customers with a complete composite tooling solution from concept to delivery.